Product

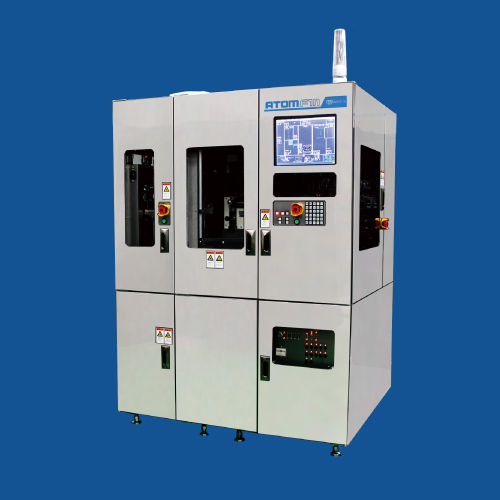

Molding Equipment

Outline

Our patented Super Flat Press delivers high-precision clamp balance, enhancing product quality and ensuring consistent production. It also removes the need for mold shim adjustments, helping streamline operations on site.

Feature

- Achieved machine size reduce by high force press (150 ton)

- Short distance to mold die and improve accessibility

- Standard unit of incomplete fill detection unit

- Press selection available according to production volume

- Achieved user-friendly operation with graphical user interface

- Product type conversion available in 30 minutes

- Press independent operation mechanism

| Items | unit | Specification | |||

| Number of press | press | 1 | 2 | 3 | |

| Machine time | sec | 20 | |||

| Press clamping force | kN(ton) | 1470(150) | |||

| Transfer force | kN(ton) | 39.2(4) | |||

| Frame size | mm | 300×100 | |||

| System size | Width | mm | 2,316 | 3,022 | 3,728 |

| Depth | mm | 1,595 | 1,595 | 1,595 | |

| Height | mm | 2,030 | 2,030 | 2,030 | |

| Weight | kg | 6,400 | 10,500 | 14,600 | |

※Please note that machine size or weight might be changed based on specifications.

Outline

One frame molding system for small lots and multiple products

Feature

- High-mix low-volume production support

- Easy product type conversion and molding die replacement

- Product type conversion time: about 10 minutes

- Achieved operation user friendly with graphical user interface

- Easy transferring with hand lifter due to small-lightweight machine

- Possesses operating parameters for small quantities, multiple products, and multiple uses

- E-pin release force detection, Image unfilled detection, abundant optional functions available

| Items | unit | Specification | |

| Number of press | press | 1 | |

| Machine time | sec | Cure+22sec | |

| Press clamping force | kN(ton) | 396(40) | |

| Transfer force | kN(ton) | 29.4(3) | |

| Frame size | mm | (MIN): 120(L)×20(W), (MAX): 250(L)×75(W) | |

| System size | Width | mm | 1,400 |

| Depth | mm | 1,200 | |

| Height | mm | 1,900 | |

| Weight | kg | 2,100 | |

※Please note that machine size or weight might be changed based on specifications.

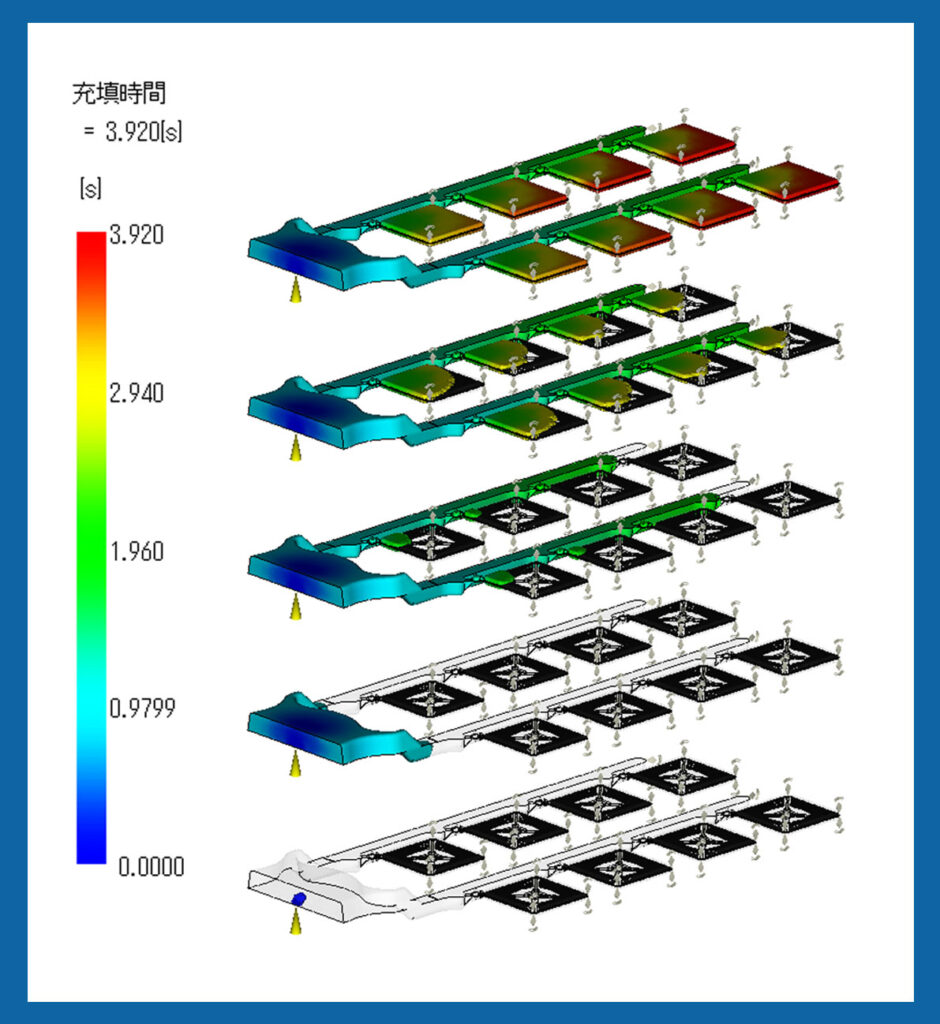

Outline

The high force 150-ton molding press is available to use a large-scale matrix lead frame and to do stably molding

Feature

- Achieved machine size reduce by high force press (150 ton)

- Production available in 4 strip/press

- Short distance to mold die and improve accessibility

- Standard unit of incomplete fill detection unit

- Press selection available according to production volume

- Achieved user-friendly operation with graphical user interface

- Product type conversion available in 30 minutes

- Press independent operation mechanism

| Items | unit | Specification | ||||

| Number of press | press | 1 | 2 | 3 | 4 | |

| Machine time | sec | 20 | ||||

| Press clamping force | kN(ton) | 1470(150) | ||||

| Transfer force | kN(ton) | 39.2(4) | ||||

| Frame size | mm | 260×90 | ||||

| System size | Width | mm | 2,000 | 2,600 | 3,200 | 3,800 |

| Depth | mm | 1,560 | 1,560 | 1,560 | 1,560 | |

| Height | mm | 1,980 | 1,980 | 1,980 | 1,980 | |

| Weight | kg | 5,500 | 8,500 | 11,500 | 14,500 | |

※Please note that machine size or weight might be changed based on specifications.

Outline

Manual molding system for development and trial purposes

Feature

- Press force 100ton

- Available wide lead-frame 80mm

- The press and the transfer driving is servo motor, and available to set detail parameter

- The mold die that was used for the trial, can be installed ATOM-FS, FX, and FXG

- Achieved operation user friendly with graphical user interface

| Items | unit | Specification | ||

| Number of press | press | 1 | ||

| Press clamping force | kN(ton) | 980(100) | ||

| Transfer force | kN(ton) | 39.2(4) | ||

| Frame size | mm | 262×80 |

||

| System size | Width | mm | Main: 730 | Control box: 550 |

| Depth | mm | Main: 1,150 | Control box: 1,004 | |

| Height | mm | Main: 2,033 | Control box: 1,400 | |

| Weight | kg | Main: 3,000 | Control box: 100 | |

※Please note that machine size or weight might be changed based on specifications.

Semiconductor assembly Equipment

Outline

Laser mark Equipment is equipped with a dust collector and a cyclone, and is clean by separating the mark area.

Feature

- The frames are carried one by one, placed on the stage, and printed in the marked area

- It is equipped with an image sensor for checking characters after the laser mark

- By exchanging the kit, you can switch the product type

- It can also be used as a deburring device for the outer frame of the product area

| Items | unit | Specification | |

| Frame size | Width | mm | 40~90 |

| length | mm | 250(MAX) | |

| Magazine size | mm | 350(MAX) | |

| System size | Width | mm | 1,365 |

| Depth | mm | 1,000 | |

| Height | mm | 1,450 | |

| Weight | kg | 900 | |

※Please note that machine size or weight might be changed based on specifications.

Outline

It is equipment that stably peels off the back tape remove of the mold lead frame such as QFN

Feature

- Conditions for removing the tape such as temperature and operating speed can be set

- The mechanism which detects that the tape is not removed is carried

- Small and lightweight equipment

| Items | unit | Specification | |

| Frame size | Width | mm | 40~80 |

| length | mm | 150~250 | |

| Thickness | mm | 0.5~2.0 | |

| Peeling speed | mm/s | 1~100 | |

| Heat stage temp | ℃ | 200(MAX) | |

| System size | Width | mm | 900 |

| Depth | mm | 1,100 | |

| Height | mm | 1,800 | |

| Weight | kg | 300 | |

※Please note that machine size or weight might be changed based on specifications.

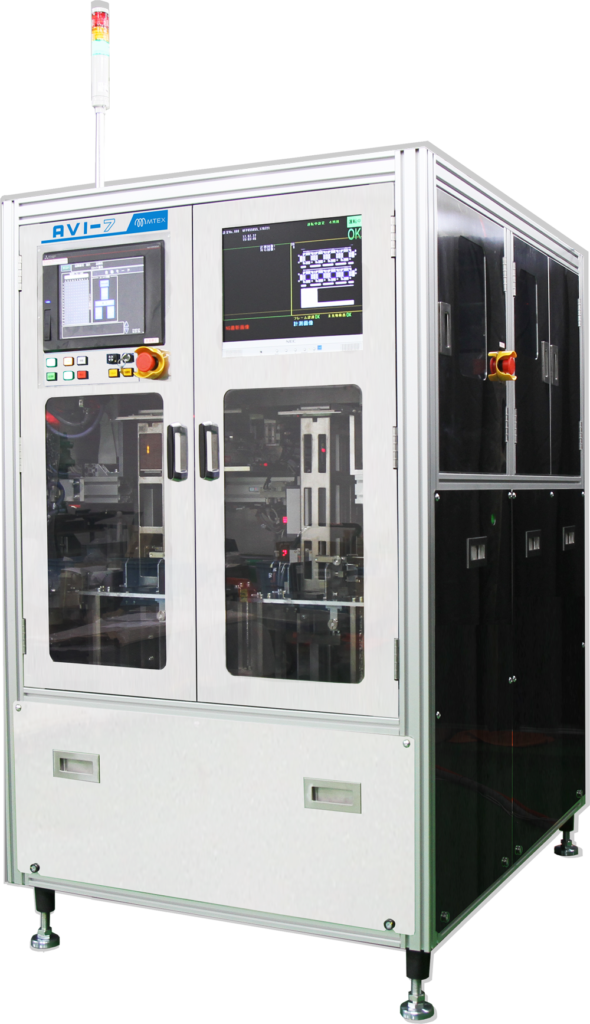

Outline

It is equipment to detect the unfilled part in the package of the mold frame

Feature

- Creates MAP data that matches the frame pattern, detects unfilled areas, and marks them

- By exchanging the kit, you can switch the product type

- In order to prevent users with incorrect settings, we provide a pre-confirmation function for registered products, images, and change kits to be used

- Small and lightweight equipment

| Items | unit | Specification | |

| Frame size | Width | mm | 35~80 |

| Length | mm | 125~250 | |

| Throughput | mm/50frame | 1~100 | |

| Detection size | □mm | 0.2(MIN) | |

| System size | Width | mm | 1,000 |

| Depth | mm | 1,230 | |

| Height | mm | 1,650 | |

| Weight | kg | 800 | |

※Please note that machine size or weight might be changed based on specifications.

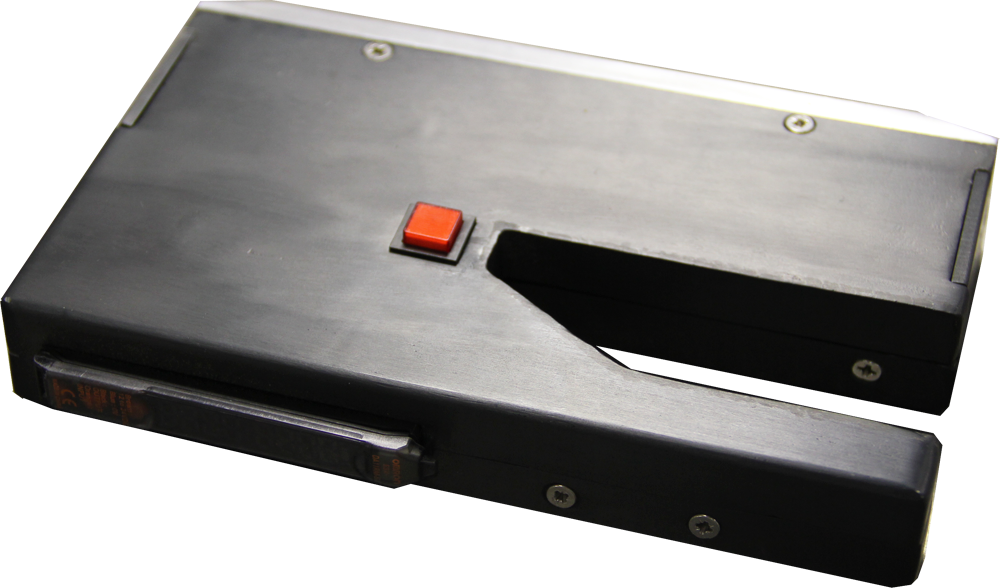

Outline

A handy type, cordless lead frame counter.

Feature

- You can easily count the number of lead frames by sliding while pressing the button

- It is a handy type and cordless, so it is easy to carry.

- Small and lightweight type. registered products, images, and change kits to be used

| Items | unit | Specification | |

| Detection specifications | Response time | ms | 1~5 |

| Frame thickness | mm | 0.1(MIN) | |

| Frame-to-frame pitch | mm | 0.5(MIN) | |

| Power supply (battery) | ー | Rechargeable nickel-metal hydride rechargeable battery[9V] | |

| System size | Width | mm | 165 |

| Depth | mm | 25 | |

| Height | mm | 100 | |

| Weight | g | 320 | |

※Please note that machine size or weight might be changed based on specifications.

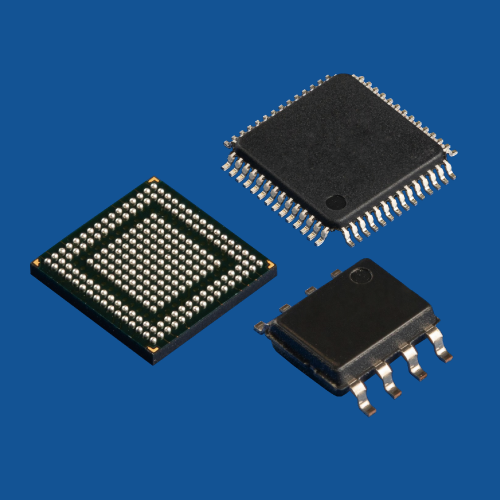

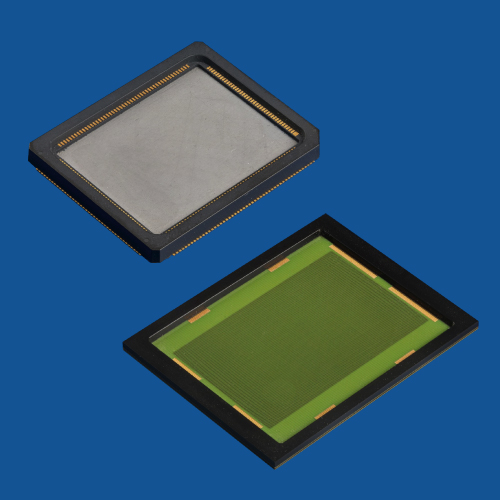

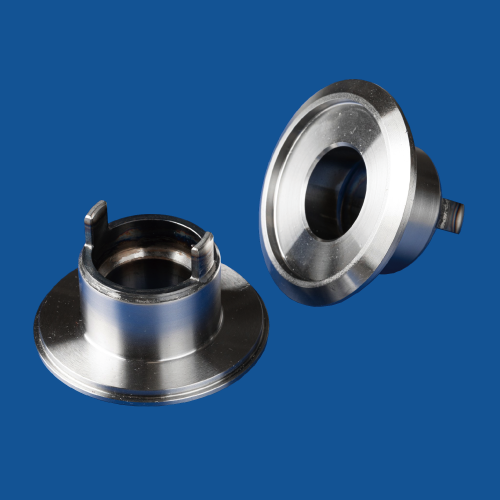

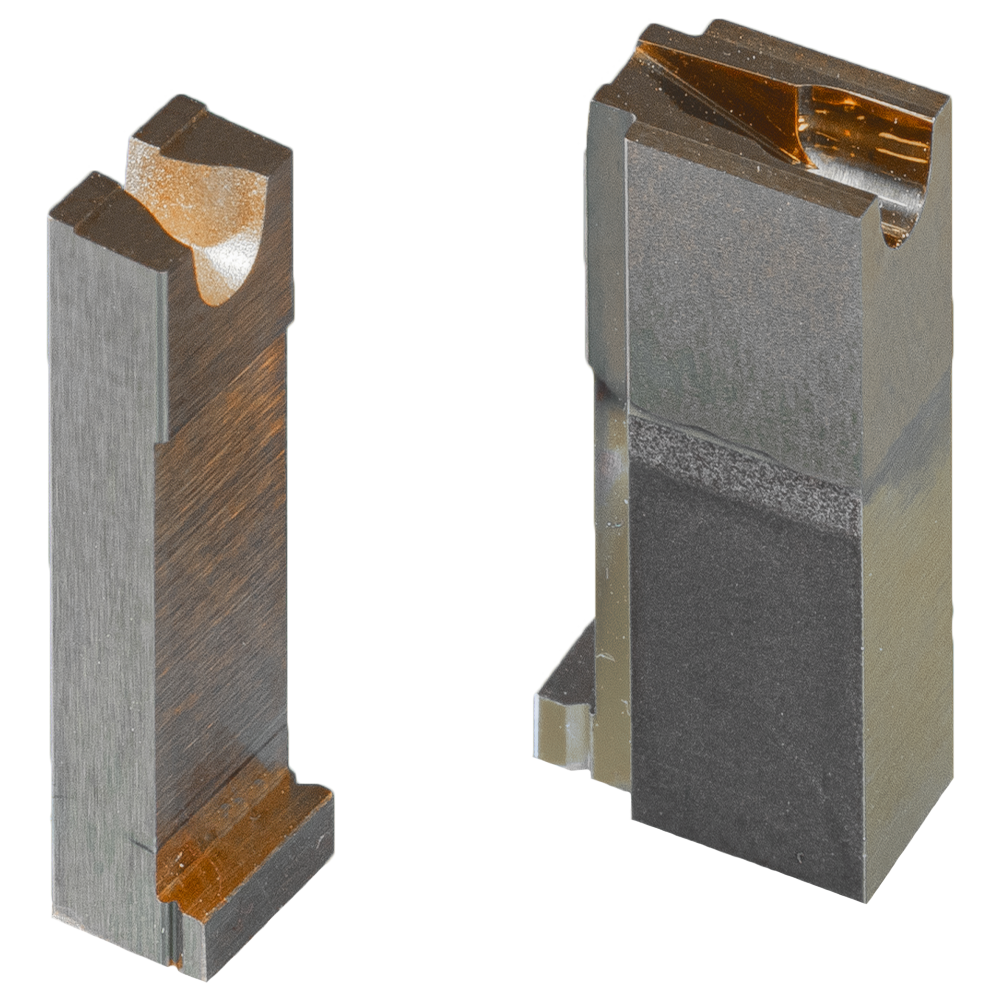

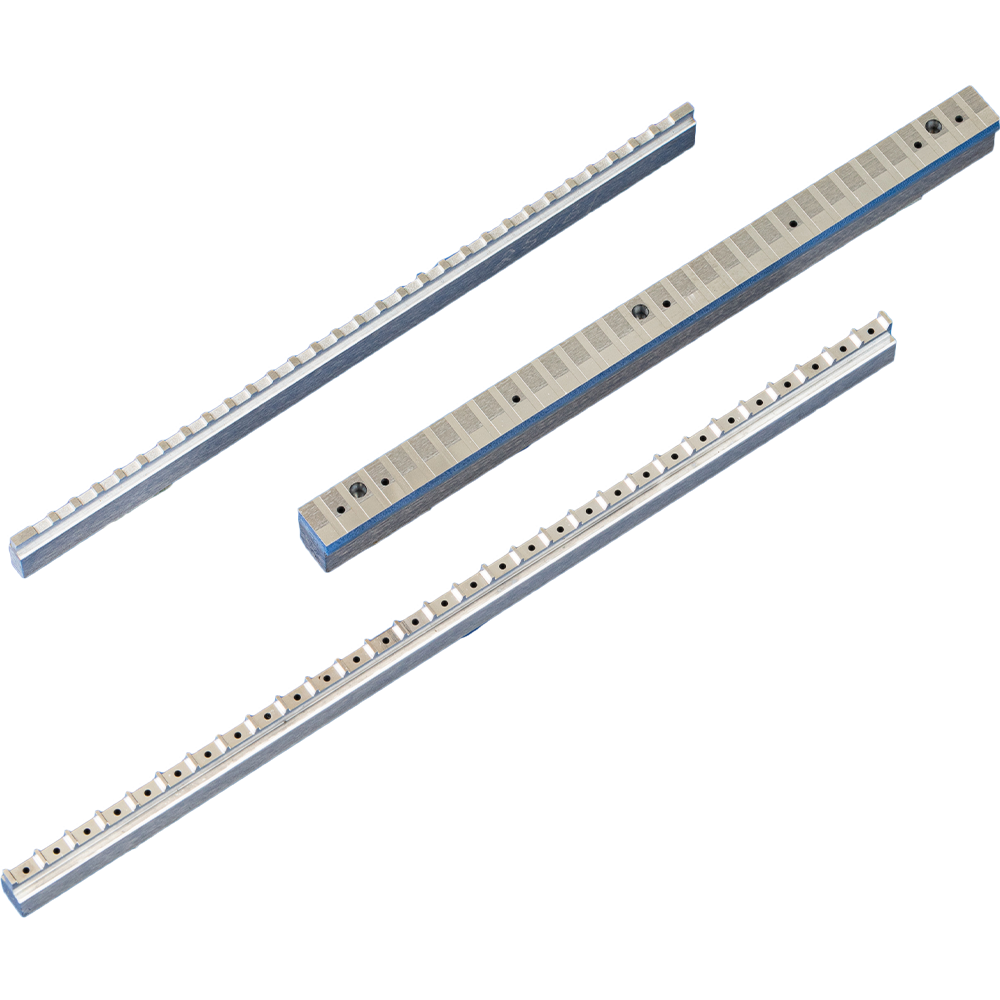

Molding die, Precision mold parts

Outline

We manufacture precision molds using the technology cultivated through many years of

experience and precision processing.

We will make proposals that suit our customers based on our track record of providing

mold materials and surface treatments to various industries.

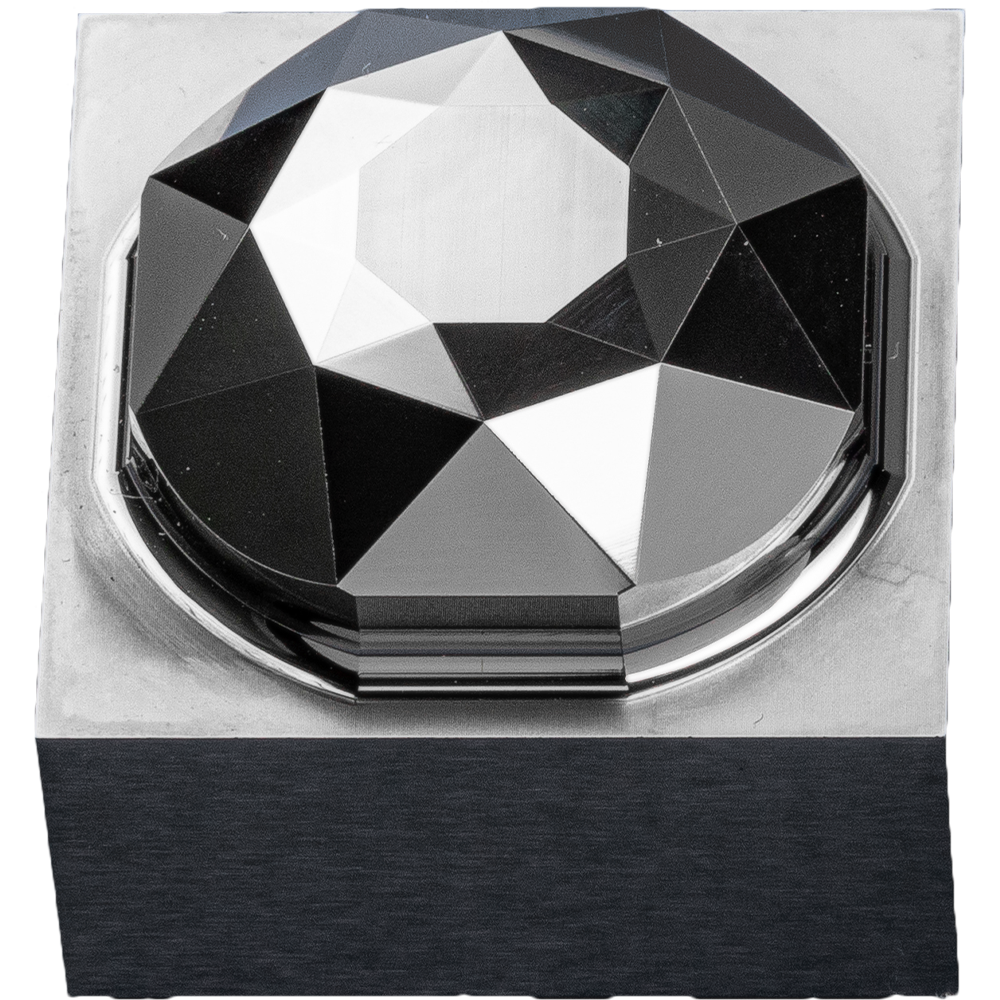

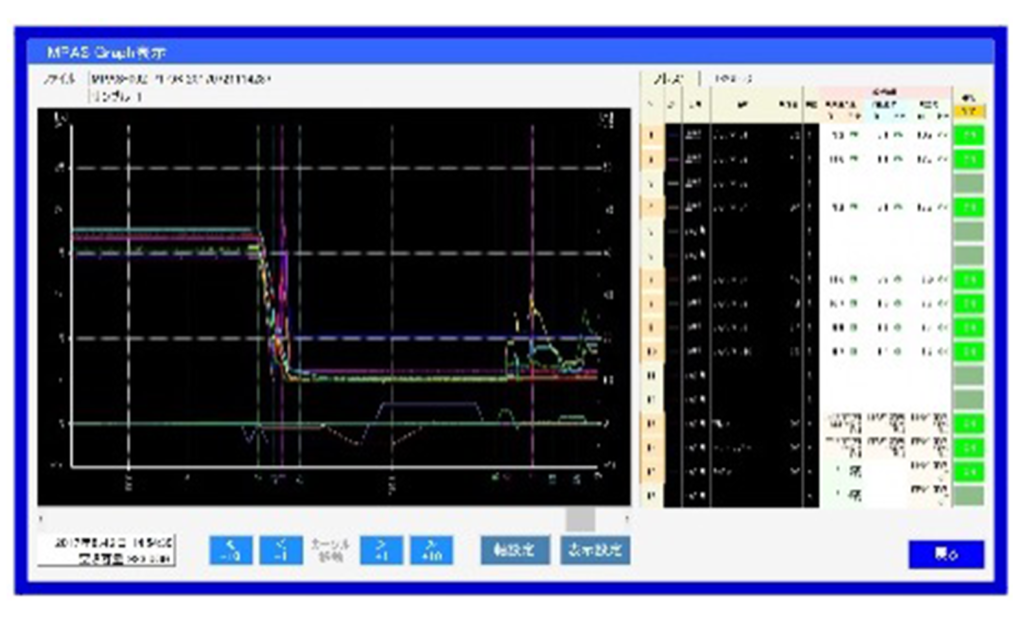

Mold Process Analysis System

Outline

Using our highly heat-resistant, compact pressure sensor and analysis software, we analyze and provide data on the pressure of the resin generated in the mold and the force generated when the frame after molding separates from the mold.

It provides data such as graphs and numerical values of differences in molding resin and differences in continuous shots.

Focusing on ultra-precision processing technology, we are developing four businesses: semiconductor assembly business, plastic molding business, equipment business, and automotive parts business. Our strength is that we can develop new products that combine each other's technologies and build highly efficient production lines using our unique technologies while developing our business independently.